A New Era for the Pultrusion Process

In 1959, Mr. William Brandt Goldsworthy patented the pultrusion process. The key to conventional pultrusion is that the part profile is cured as it is pulled through a stationary die. A constant cross-section, linear profile is continuously produced by this system.

Pultrusion has been limited in that the profiles it generates are straight, not curved. Over the years, various composite manufacturers have approached this challenge but have been unable to obtain a continuous curved pultrusion process.

Over six decades later, Royalcom Ltd, invented a special version of the curved pultrusion process (patented). Respecting conventional technology, Royalcom's new innovative process is based on a continuous manufacturing process in which fiber-reinforced plastic with a constant cross-section is pulled.

Royalcom Patented Technology

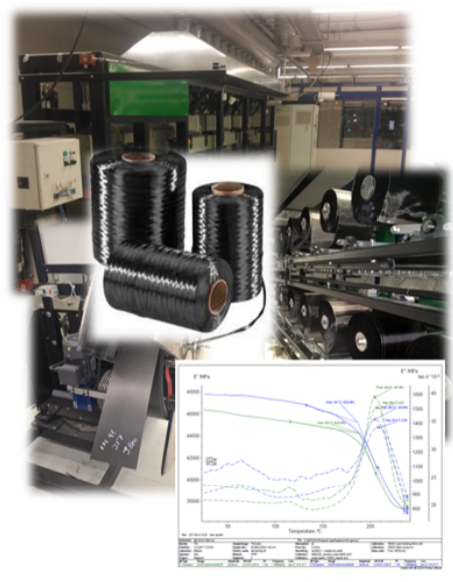

Royalcom is using fully automated novel technology for manufacturing, e.g. helical and leaf springs for the automotive industry and curved/ full circle for the aviation and the construction industry.

The technology enables a totally new approach to find the optimal mixture of fibers and various high-temperature resistance resins and dimension-free production.

High quality is ensured together with the material laboratory of South-Eastern Finland University of Applied Science.

Composite Leaf Spring, Curved and Full Circle Profiles

- Test runs done with different fiber reinforcements (Carbon, Glass) and shapes (round and oval)

- Round leaf spring profile Ø 20mm

- Oval leaf spring 12x24 mm (Carbon) and 13x30mm (Glass)

- Full circle profile Ø 3000 mm

- Carbon fiber (48/50 K) and Glass fiber (4800 TEX)

- Epoxy resin matrix (TG 150-230°C)

- Fiber content volume up to 70%

Composite helical spring

- Test runs done with different fiber reinforcements (Carbon, Glass)

- Wire diameter Ø 10 mm

- Helical spring mean diameter Ø 110 mm

- Pitch 40 mm

- Carbon fiber (48/50 K) and Glass fiber (4800 TEX)

- Epoxy resin matrix (TG 150- 2300C)

- Fiber content volume up to 70%

Company

- Established in 2010

- First commercial start-up of technology development in 2011

- Composite doctoring products business for the Pulp&Paper industry sold in December 2020

- Privately owned by management

- Royalcom develops beyond the limits composite solutions for efficient continuous manufacturing

- Long-term competence in composite materials

- Carbon / glass fiber weave

- Carbon / glass fiber roving

Contact details

Ilkka Eskelinen

ilkka.eskelinen@royalcom.fi

Timo Laitiainen

timo.laitiainen@royalcom.fi